Aquaspira helps museum acquire important First World War medals

Aquaspira were very pleased to be able to assist the Keep Museum in Dorchester in acquiring the Military Cross of Captain John Fergusson, a small but important piece of human...

ExploreSingle or Multi-Leg Push-Fit Tank Systems

Sealed, Push-Fit tanks, installed in any weather, with no requirement for welding on site.

Manifolds are quickly set in position and pipes are placed and joined in record time.

Units are very robust during installation and throughout their design life.

Efficient installation reduces project programme time.

High-quality materials provide unrivalled long-term performance with minimal maintenance.

Attenuation Tank Components |

|||

| Image | Description | Pipe Diameters | Sample Fabrication Drawings |

| Single Side Manifold with Access Turret | 900 - 2250 mm | |

| Double Side Manifold with Access Turret | 900 - 2250 mm | |

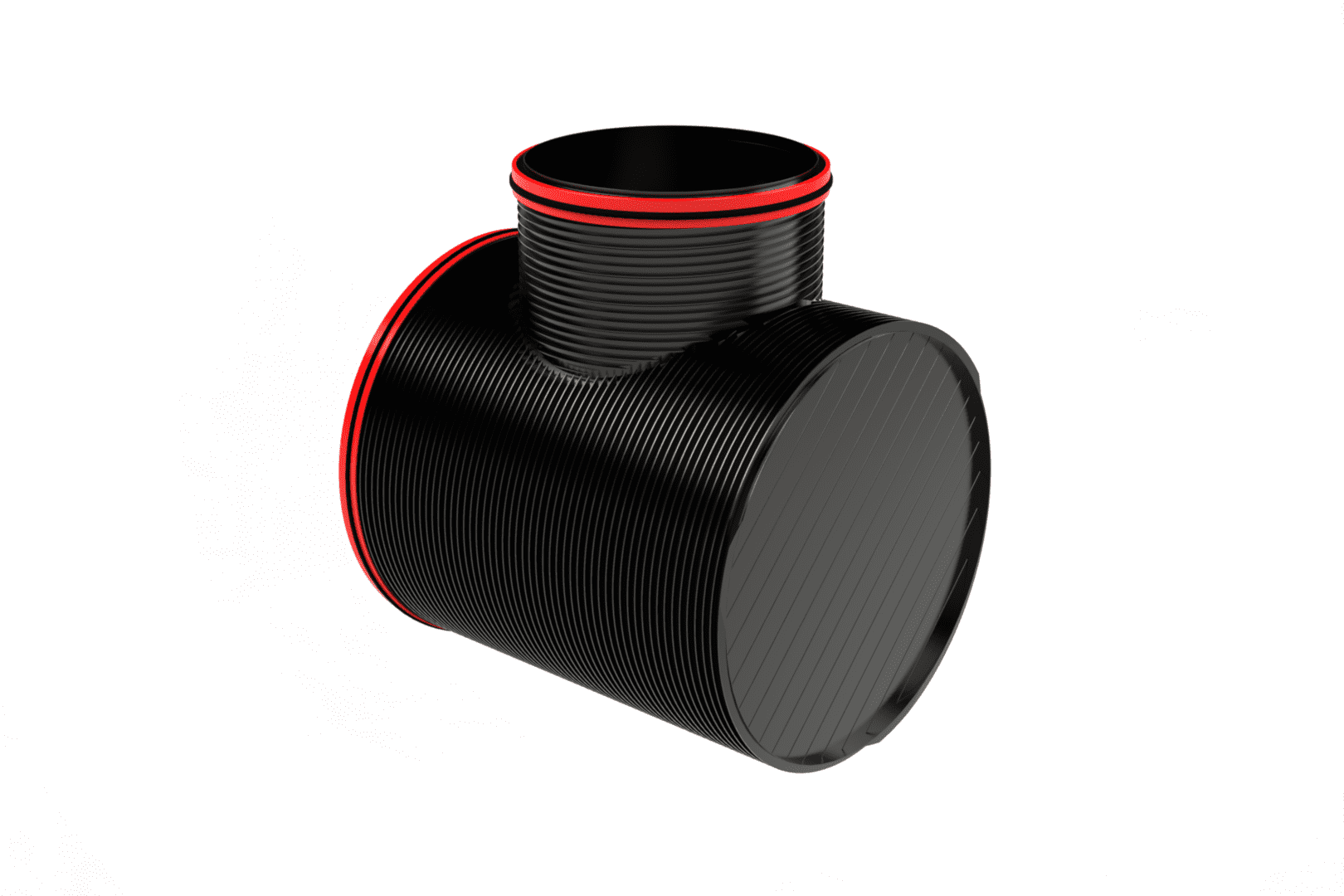

| Access Tee Pipe | 900 - 2250 mm | |

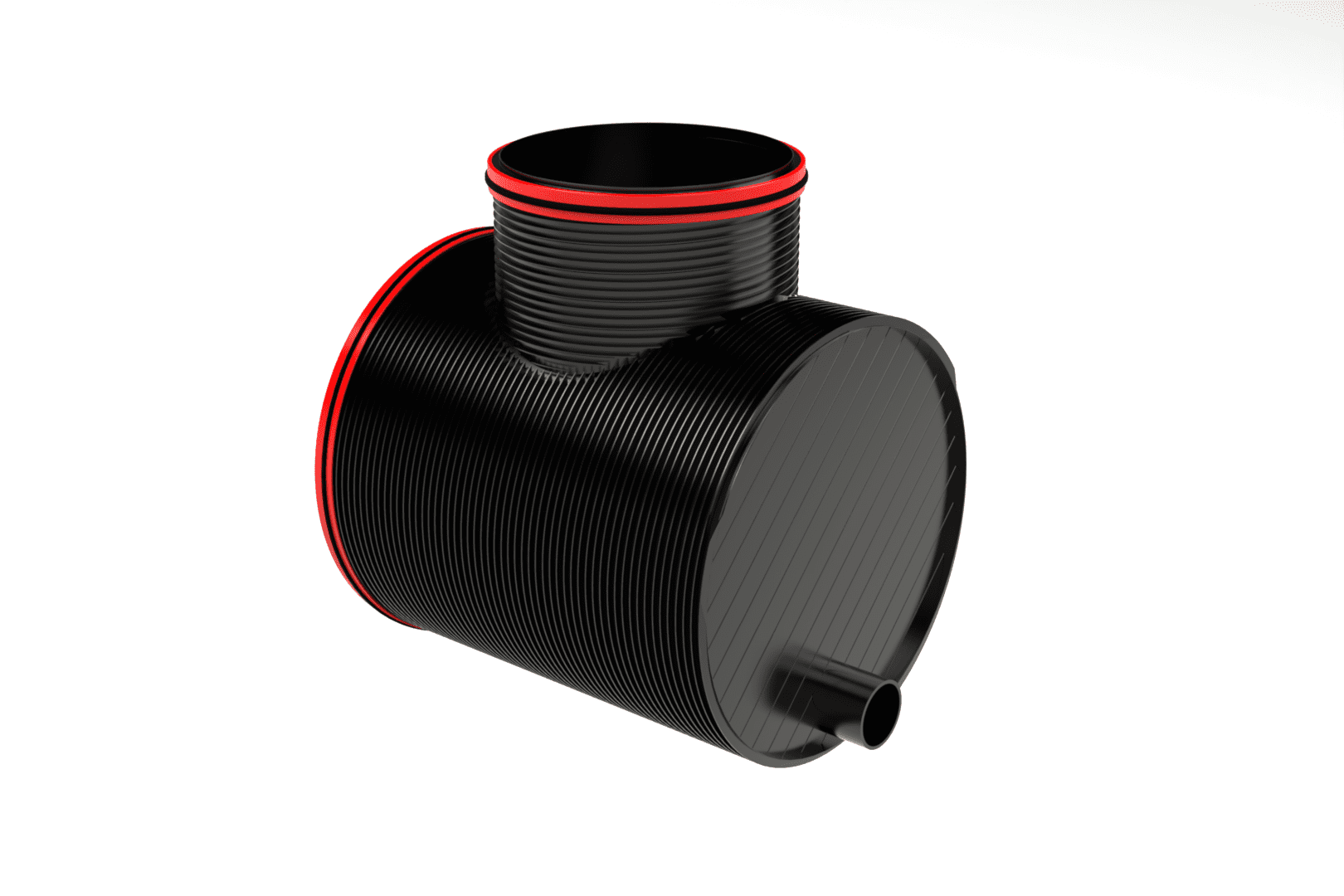

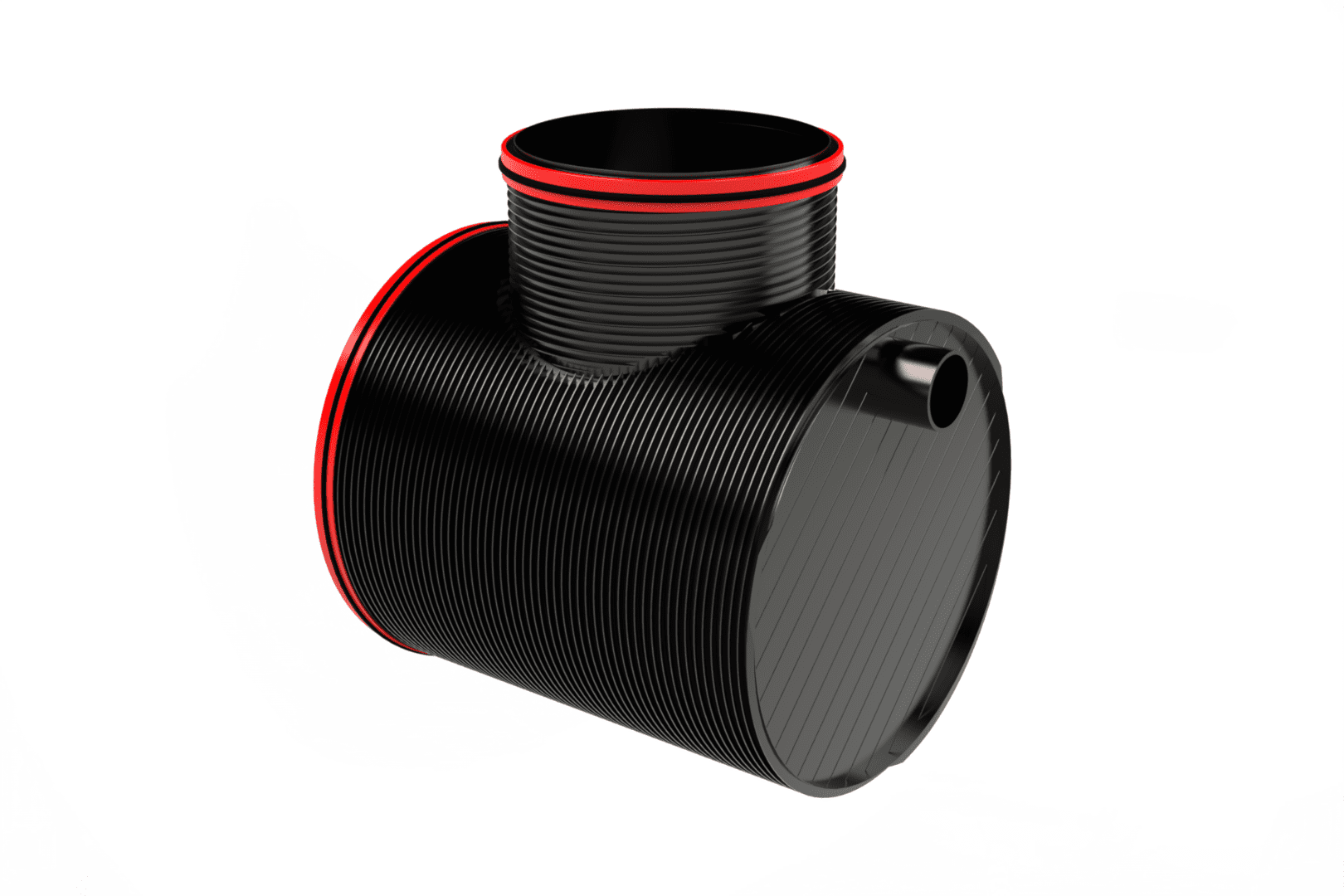

| Access End Pipe | 900 - 2250 mm | |

| Access End Pipe with Invert Level Outlet | 900 - 2250 mm | |

| Access End Pipe with Sofit Level Inlet | 900 - 2250 mm | |

| Typical Construction Detail | |||

The company’s greatest asset is not our state-of-the-art production facility or the engineered excellence of each product that it produces, but rather our people, who are individually committed to ensuring the highest standards of quality, service and support to our customers.

In a world that is increasingly concerned about its environment, it is reassuring to know that despite the enhanced performance of Aquaspira CSR large diameter pipes, on average they use 17% less material by weight than structured wall plastic pipes and only a fraction of that required to manufacture concrete or clay drainage products.

Spearheading the company is a highly experienced management team with over 100 years combined service acquired with market leading businesses in the drainage and pipe manufacturing sector, so you can rest assured, knowing you are in vastly experienced hands.